1. Application

This device is applied to the steaming and washing finishing of pure cotton, bast and its mixed fabrics with man-made fiber after cold pad-batching.

2. Technical features

①. Use the building block structure, you can combine the production lines according to the requirements of different products and technologies.

②. Common used nominal width: 1800-3600mm.

③. Processing speed: 15-65m/min.

④. Common used diameter of roller: φ150-φ200mm.

⑤. Man machine interface control, fabric load capacity, machine speed, load time can be adjusted according to the technology. Choose the efficient steaming washing box, diameter and quantity of the dryer cylinders, efficient padder, Water heat exchanger and sewage filtering equipment.

3. Effect of energy-saving

①. Brush washing machine - brush MaoPing wash tank

The machine washed steam box have three rows of guide roller, fabric and in accordance with the roller wear between serpentine cloth, and the middle row brush roll into plane contact, the fabric brush of liquid surface effective brush processing, dust and flower hair suspended in the water the cabinet, through the homemade patent high-performance filter will be suspended in the liquid continuous filtration separation, and will be filtered water reuse on spray, so as to achieve the purpose of cleaning cloth and water saving. (installation in setting machine before the end, the cloth equipped with rubber roll small mill car up traction and rolling fluid effect.

The equipment is mainly applied in grinding wool, wool and wool flocculated more fabrics, can be used for singeing machine, washing machine water and setting machine forepart add one or two lattice water tank to reduce continuous washing technology, at the same time in glass fiber production process has also successfully applied.

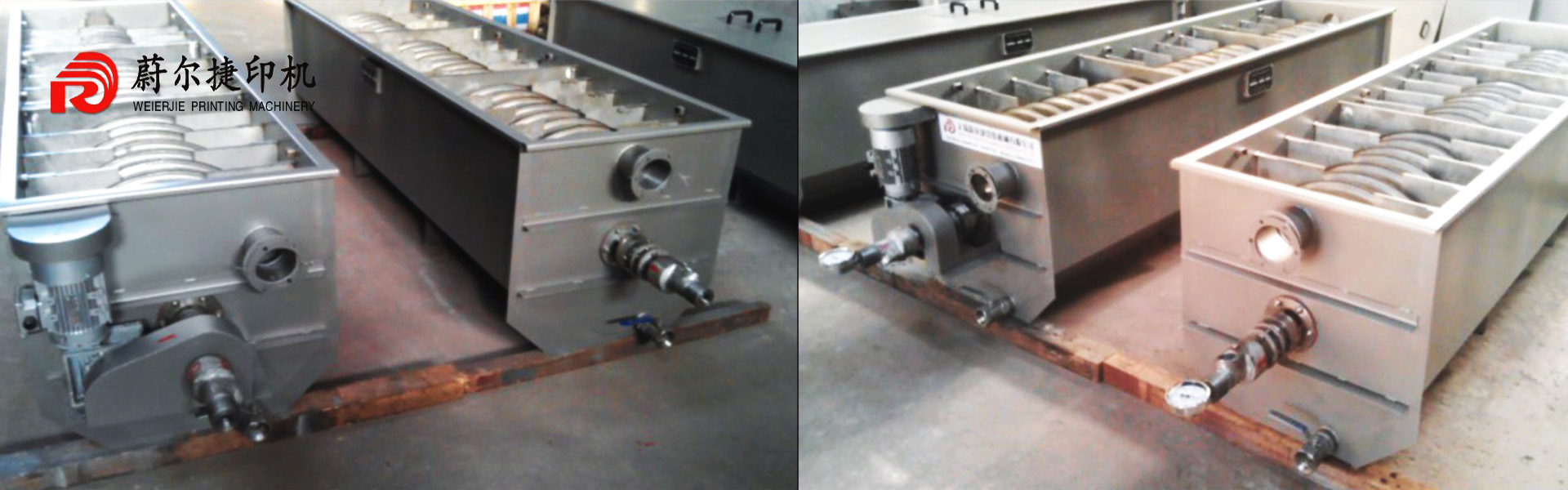

②. Drum type network barrel water box (short process)

This machine is suitable for pure cotton, polyester cotton, chemical fiber and all kinds of fabrics of the oscillation type water use. Inside the case and large diameter cylinder roller, coated surface, not easy edge and wrinkling, and permeability is good. Drum running water to produce the oscillation method for fabric to wash, and cabinet filter tank for water filtration and reuse, and in each root nets barrel roll above are connected with many groups of spray pipe powerful flush, liquid circulation use, so as to reduce the conventional washing process, save the area, reduce energy consumption and pollution, more effectively remove the dirt from the fabric. The whole machine is the current frame design, the different pollution degree of water space, form into cloth from the cloth to stage the degree of dirty water gradually reduce, to ensure the posterior segment of the fabric and clean water contact and reduce the secondary pollution.